Chasewood’s has the technology, resources and experience to deliver Chasewood core business, casing operations, dates back to its 1997 establishment as a casing company. Over a decade, CWL evolved into a worldwide leader with the most complete inventory of casing and handling tools sufficient for tubular sizes.

Chasewood offers customers a complete casing and handling package, consisting of tools such as spiders, elevators, tongs, stabbing boards, protectors and related accessories.

CHASEWOOD Tubular Services’ has become international, expanding beyond the walls of the Gulf region. It is a significant mark in the Oil & Gas Industry which depends on experience, high technology, and team work to meet all challenges of the oilfield sector.

The most technologically advanced Casing and Tubular Service Department of CWL is proud to serve throughout the oil producing region of the countries.

Tubular handling technology has advanced rapidly in recent years. The increase in use of premium grade connections and expensive tubular have resulted in demand for more sophisticated handling and running techniques. CWL is proud of being able to offer the latest technology using computerized torque-turn analysis system that records every parameter of connection make-up. CWL has the newest and most advanced Torque Turn Monitoring System to run Carbon steel, Fiber glass and CRA tubulars. The division also has specialized expertise to handle chrome Single, Tandem and Dual Completions. An ongoing training program has been established to field personnel to ensure that tubular service skills are continually improved to maximize efficiency and minimize rig time.

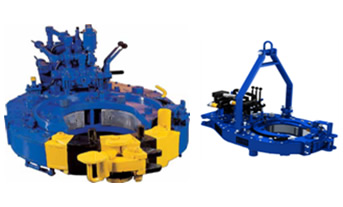

Always on the forefront of oilfield research, CHASEWOOD is proud to use the latest technology equipments to handle CRA Tubular (corrosion resistant stainless steel alloy) using Chromemaster System, which is the most competitive Hydraulic Power Tong. It allows the use of aluminium smooth non marking “O” zero penetration dies to prevent marking and avoid any contamination of CRA tubular string with other materials, which could initiate corrosion problems.

CHASEWOOD Tubular Services provides the option for remote operation of High Torque Hydraulic Power Tong by single operator at customer’s request. The High Torque Hydraulic Power Tong is equipped with T/T Computer and has ports for proximity switch. It also has encoder adapter for high turns resolution along with optional electronic Solenoid Dump Valve.

To satisfy our client’s requirements, CHASEWOOD Tubular Services provides 20” & 14” UHT Clincher Tong with integral Backup Tong for High Torque Valve Premium Connection Pipes. We also provide Electric Hydraulic Power Units for Zone I hazardous environment, and Zone II Hydraulic Power Unit (Diesel). Both of these comply with the Oil & Gas Industry specifications.

In addition to the above, CHASEWOOD Tubular Services provides all the Handling Equipments required to perform running casing and tubing in hole services, such as, different types of Air Operated 500 Ton 24-1/2” ~ 12-1/4” Spider / Elevator, 500 / 350 Ton 14” ~ 4-1/2” Spider Elevator, Side Doors and Single Joint Elevator, Rotary Hand Slip, Safety Clamps, 500 Ton Flush Mounted Spider for different types of Rotary Table, Fill Up and Circulator Device, 250 Ton Dual Handling Tools (4-1/2” ~2-3/8” Tubular), Horizontal Bucking Unit Services, Air Operated Pipe Alignment Tools, Hydro & Gas Testing equipments, Internal Cleaning Equipments, Thread Dope Diffuser, Casing Cold Cutting Machine, Hydraulic Torque Wrench, Truck Mounted Pick Up & Lay Down Machine etc… Our full range of services and supplies are available to all the companies that are looking for the right solution.